Project Delta

When I bought this sexy lab trailer, I was dealing with a red-alert… my business lease in Friday Harbor had become unstable, and it was impossible to find a rental on this rock except for overpriced triple-net absurdities. Erecting a pole building on my dear friend’s land was out of the question (36-week permitting delays,…

Read MoreFeline Existential Angst

Inspired by being roused from a nap to be hauled off in the carrier to spend a day with me at the lab, Isabelle threw herself wholeheartedly into completing volume 2 of her critically acclaimed treatise on feline existential angst. For continuity with Kant, Hegel, and other voices, she is writing Existenzielle Angst der Katze…

Read MoreSnapshots of Extreme Audio

As an engineer, one of the most absurd things on the Interwebs is the profusion of tech nonsense… wishful thinking, art projects presented as reality, and the industry of audiophile pseudoscience. I love stereo systems that are on the performance asymptote as much as any other paleogeek who grew up with vinyl, but I bristle…

Read More1974 Vic Franck Delta 50

Floating Technomadic Lab/Office for Sale! Posts in this wide-ranging archive have covered my move to the “Dark Side” – selling my Amazon 44 named Nomadness on the quest for floating lab space. I bought this gorgeous Delta 50 in early 2016, named her Datawake for the “wake of data” streaming astern, then spent four years…

Read MoreBikepacking article – first digital nomad

This beautifully written 2023 article by Lucas Winzenburg in Bikepacking captures the flavor of my 17,000-mile adventure from the technological and cultural perspective of 40 years down the road. It has sparked considerable discussion and a few interview requests about digital nomad history, and I am honored to provide this link to the source. The…

Read MoreBuilding a Mobile Digitizing Lab

Here in late 2022, as a sort of technomadic swan song, I have embarked on a new adventure in mobile geekery. There will be no pedaling this time, nor is this another floating extravaganza of boat hacking and nautical gizmology. Instead, I’m creating a 48-foot mobile laboratory packed with the tools of my trade… digitizing…

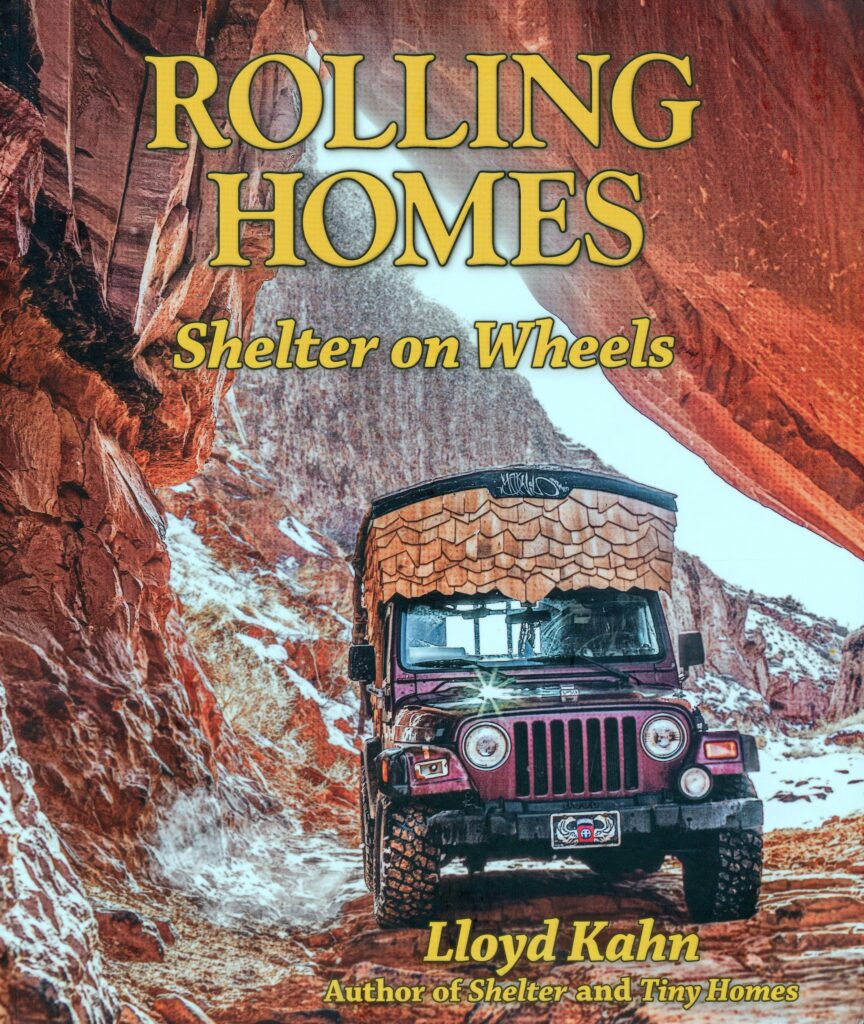

Read MoreWinnebiko in Rolling Homes by Lloyd Kahn

Shelter Publications has been producing dreamy wish books of tiny homes and efficient nomadic tools since 1973, and if you have ever fantasized about taking off in a home on wheels, you almost certainly know his work. Rolling Homes is Lloyd Kahn’s latest volume, published in August 2022, and I am delighted that it includes…

Read MoreHarbor Digitizing in Microsiervos

This site in Spain posted a story about my digitizing activities, and quite surprised me with a flurry of web traffic and a few inquiries about home movie archives. According to Google Translate, the title reads, “The veteran technomad who could digitize any audio, video, film or photo format.” Since this is such a good…

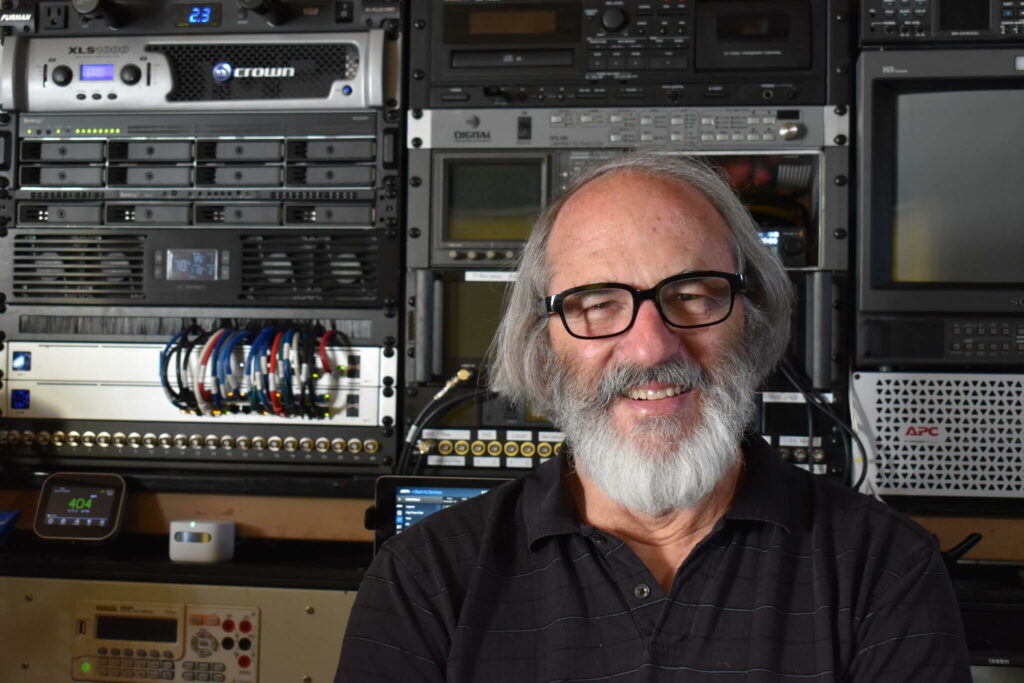

Read MoreWizard with a Time Machine

By Kelley Balcomb-Bartok Journal of the San Juan Islands July 19, 2022 Located in an unassuming building in Friday Harbor is a magical place inhabited by a wizard of technology bringing history back to life for clients and friends. Steven K. Roberts is his name, digitizing old films, videos and slides is his game. Harbor…

Read MoreReality 2.0 Interview with Doc Searls

“Digital Archives and Nomads” Ages ago, on the Perl Whirl and Linux Lunacy geek cruises, I had the pleasure of hanging out with the legendary Doc Searls, editor of Linux Journal and co-author of Cluetrain Manifesto along with lots of other things. He also created the FLOSS Weekly podcast, has been a vocal proponent of…

Read More

You must be logged in to post a comment.